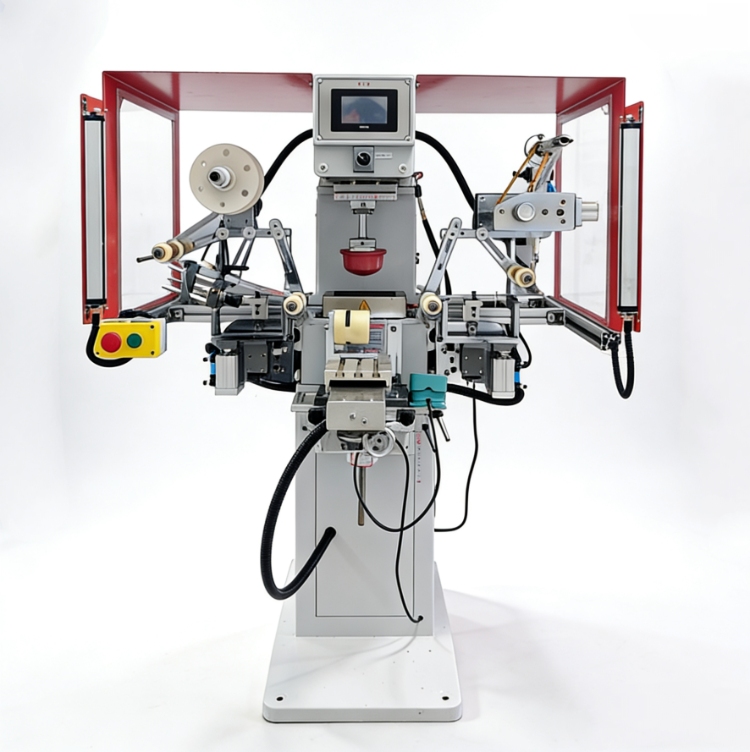

Product name:Round Phonematic Hot Stamping Machine

Model Number: H-180H

1. Usage

This is a semi-automatic hot stamping machine by phonematic driven, specially designed for cylinder round and cone shape capsule’s hot stamping on sidewall of the various products such as plastics caps, painted metal accessories. Through precision constant temperature control and constant tension foil feeding/rewinding system, it can complete thermal transfer/hot stamping, texts and decorative borders in one running time through, ensuring smooth edges, firm adhesion and no wire drawing on the metal layer.

2. Applicable :

• Maximum product outer diameter: Ø180 mm

• Product thickness: ≤ 60 mm (customizable for special requirements)

• Applicable materials: ABS, PP, PMMA, PET, painted parts, etc.

• Hot stamping area: Product side walls and chamfers

3. Parameter :

1. Maximum processable outer diameter: Ø180 mm

2. Electric furnace (oven) size: 200 mm × 100 mm

3. Heating power: 1300 W (PID constant temperature control)

4. Temperature setting range: 0–250 ℃, accuracy ±2 ℃

5. Hot stamping rubber roller: Φ100 mm aluminum core high-temperature resistant silicone roller

6. Main cylinder: Bore diameter Φ40 mm, stroke 75 mm, adjustable ≤50 mm

7. Tension motor: 6 W speed-regulating gear motor

8. Film rewinding motor: Closed-loop servo/stepper motor with encoder

9. Rubber roller drive: 15 W gear motor

10. Fixture rotation: 15 N·m closed-loop motor + one-stage gearbox

11. Clamping method: Manual loading and unloading, ejector cylinder pressing

12. Control system: PLC program control + touch-type HMI

13. Safety configuration: Emergency stop button, air switch, overcurrent and overtemperature protection

14. Power supply specification: AC 220 V ±10 %, 50 Hz, single-phase

15. Air source requirement: 0.5–0.7 MPa dry and clean compressed air

16. Machine dimensions (L×W×H): 1300 mm × 1100 mm × 1100 mm

17. Overall weight: ≈ 280 kg

18. Production capacity: 6–10 pieces/minute (taking Ø100 mm products as an example)

4. Key Components and Brands

• PLC: Delta DVP series (16 I/O, expandable)

• HMI: Color touch screen

• Closed-loop motor: Domestic motor + encoder

• Gear motor: Feiteng high-reliability gear reduction

• Pneumatic components: Domestic cylinder, Airtac solenoid valve

• Sensors: Yangming/OMRON fiber optic sensors, proximity switches

• Electrical protection: Air switch, emergency stop, relay

5. Safety and Ergonomics

• Emergency stop button, front-mounted and easily accessible

• Main power air switch with leakage/overload protection

6. Installation and Operating Environment

• Ambient temperature: 10–35 ℃, relative humidity ≤85% (no condensation)

• Floor bearing capacity: ≥ 500 kg/m², levelness ≤2 mm/m

• Power supply: Independent power supply with single-phase 220 V 30 A socket

• Air source: 8 mm pipe diameter connected to 0.6 MPa main air pipe