Product name:Multi Function Automatic Labeling Machine for Bottles

Model Number: ALM-71300

Multi-function Automatic Labeling Machine for round bottles, oblate bottles, square bottles , etc.Advance

The machine can simultaneously achieve two-sided circumferential surface labeling and labeling features to satisfy the flat bottles, square bottles and bottle shaped single-sided and double side labeling, the entire circumference of the cylindrical body, a half weeks labeling, widely used cosmetics industry, daily chemical industry.

Optional Tape printer and inkjet printer to achieve the production date printed on the label and batch information to achieve labeling – endowed integration.

Application

1.For label: self-adhesive labels, self-adhesive film, electronic supervision code, bar code, etc.

2.Applicable products: Requires the side plane, side sweeping surface, the circumferential surface attached label.

3.Industry: Widely used in cosmetics, daily chemical, electronics, pharmaceutical, metal, plastics and other industries.

4.Application examples: Head & Shoulders shampoo flat bottle labeling, Shell Lubricants flat bottle labeling, labeling and fresh wine.

Specification

1.label length : 20mm ~ 200mm

2.Label width (backing paper width / mm): 20mm ~ 180mm

3.Flat or Oblate bottles size :

Length : 20mm ~ 250mm

Width: 30mm ~ 90mm

Height: 60mm ~ 280mm

4. Round Bottles Size:

Diameter : 45mm ~ 100mm

Height: 60mm ~ 280mm

5.Max Outside diameter of label roll: φ280mm

6.Inside diameter of label roll: φ76mm

7.Labeling accuracy (mm): ± 1mm

8.The standard speed : 5 ~ 19m/min

9.Labeling speed: 30 ~ 160pcs/min

10.Conveyor speed : 18m/min

11.Weight : about Net weight 550KG, gross weight 800KG

12. Voltage : 110/ 220V 60Hz

13.Power : 1220W

14.Machine dimensions: 3000mm *1450mm *1600mm

15.Packing Size(L*W*H):3150*1360*1630mm

Features

1.powerful, a machine can achieve four kinds of products-sided and double-sided labeling (round bottle, flat bottle, square bottle, shaped bottle). Configure round bottle positioning style cover standard mechanism, enabling single standard round bottle labeling, double standard labeling and spot labeling;

2.uses synchronous bilateral rigid plastic chain guide, automatically guarantee a bottle of neutral, the workers put into bottles and bottles of low demand docking lines, greatly reducing the difficulty docking assembly line worker jobs or be stand-alone production, can also be connected to production line;

3.Configuring spring-capping mechanism to ensure smooth product handling and high bottle itself effectively eliminate errors;

4.configure automatic bottle institutions, guided bottle automatically before separate spacing, ensure follow guide bottles, transport and labeling of stability;

5.configure two repeat standard bodies, for the first time to ensure labeling accuracy, quadratic twist roll-covered standard, effectively eliminate air bubbles and ensure the head and tail snapping;

6.intelligent control, automatic photoelectric tracking, with no object no labeling, no label auto-correction and auto-detection function labels, tags and drain to avoid wasting stickers;

7.high stability, Panasonic PLC + touch screen + Panasonic Matsushita Electric eye needle + German Leuze label sensor composed of advanced electronic control systems, support equipment 7 × 24-hour operation;

8.equipment is mainly made of stainless steel and high-alloy, in line with GMP production, the overall structure of a solid, beautiful;

9.can be stand-alone production, can also be connected to production lines, automatic product detection, unmanned production;

10.function with downtime, production counting function, power saving features, the production of digital set stop function, parameter setting protection function to facilitate the production and management;

11.optional features and components.

|

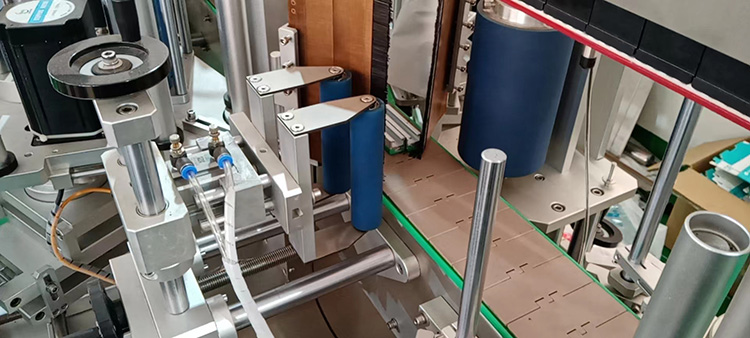

Major Mechanical Configurations |

|

Name |

Picture |

Main Material |

Function |

|

Conveyor Belt |

|

Metal plate |

Transmit the product |

|

Spacing Wheel |

|

High-density foam |

Separate and keep certain distance bet ween every 2 bottles |

|

Guiding Device |

|

Stainless Steel |

Correcting the transm ission direction,keep the bottles go straightly. |

|

Top Belt Device |

|

Stainless Steel |

Fixing the product from the top,keep it moving steadily. |

|

Label-peeling Plate |

|

Stainless Steel |

Label be peeled and stuck here. |

|

Strengthening Device |

|

Stainless Steel High Density Sponge |

Press the bottles to make label stick tighter |

|

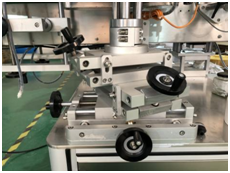

Adjustment Base |

|

Stainless Steel |

Adjust the labeling head in vertical,horizontal dire ction and angle to adapt to bottle shape |

|

Position Indicator |

|

Stainless Steel |

ndicate the position of the labeling head by specific numbers. |

|

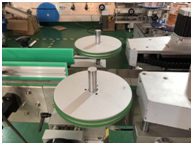

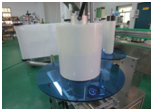

Label Tray |

|

Acrylics |

Place the label roll, the tray roll to send the label out . |

|

Roller |

|

Aluminium Alloy |

Maintain the ten sion of the label |

|

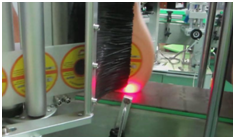

Front Label Sensor |

|

Transparent Sensor (German) |

Detect the label to control the label be peeled one by one; for opaque label. |

|

Traction Device |

|

Aluminium alloy; Rubber covered roll |

Driven by a stepper motor,pull the label reel while labeling |

|

Touch Screen |

|

|

Control machine and set production parameter |

|

Emergency Stop Switch |

|

|

Stop the machine immediately if the machine runs wrong. |

|

Round bottle positioning mechanism |

|

|

Round bottle positioning mechanism |

|

Major Electronic Configurations |

|||

|

Name |

Brand |

Quantity |

Country |

|

Front Label Sensor |

Datasensor |

1 |

German |

|

Back Label Sensor |

Datasensor |

1 |

German |

|

Product Sensor |

Panasonic |

1 |

Japan |

|

PLC |

Panasonic |

1 |

Japan |

|

Top Belt Motor |

Leadshine |

1 |

China |

|

Traction Motor |

Leadshine |

2 |

China |

|

Guiding Device Motor |

Leadshine |

2 |

China |

|

Transmission Motor |

Cheeming |

1 |

China |

|

Spacing Motor |

OPG |

2 |

China |

|

Power |

Samkoon |

1 |

China Taiwan |

|

Touch Screen |

Weinview |

1 |

China |

III Transaction Details

1.About Payment:30% deposit and 70% before delivery.

2.About Delivery Date:Delivery within 20 days after the seller confirming deposit receipt.

3.About Installment:the machine would be adjusted before delivery,instruction manual and video would be sent as well.

IV About After-sale Service:

(1)One year machine warranty and lifetime maintenance.We guarantee to replace the broken parts caused by quality problem free of charge,not including the quick-wear parts.We will charge fees for maintaining after 1 year.

(2)We will be your lifetime machine spare

parts and technology provider.