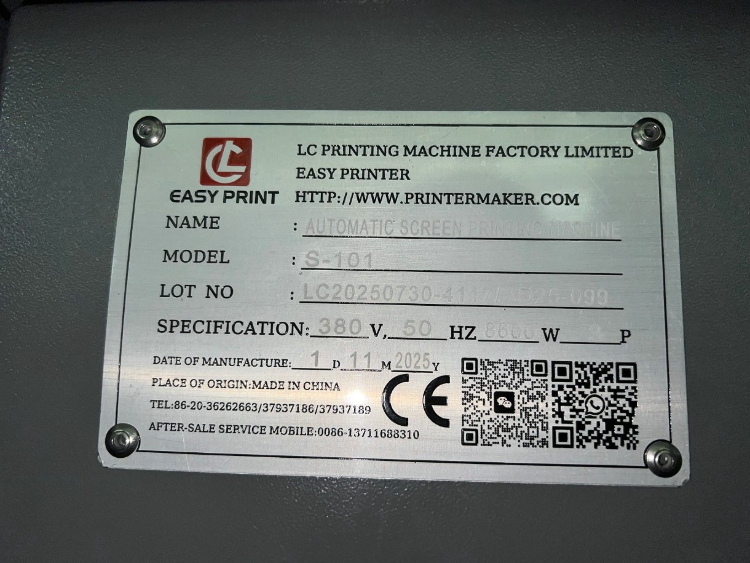

November 21, 2025 - Automatic Screen Printing Equipment Exported to Long-Term Indonesian Customer

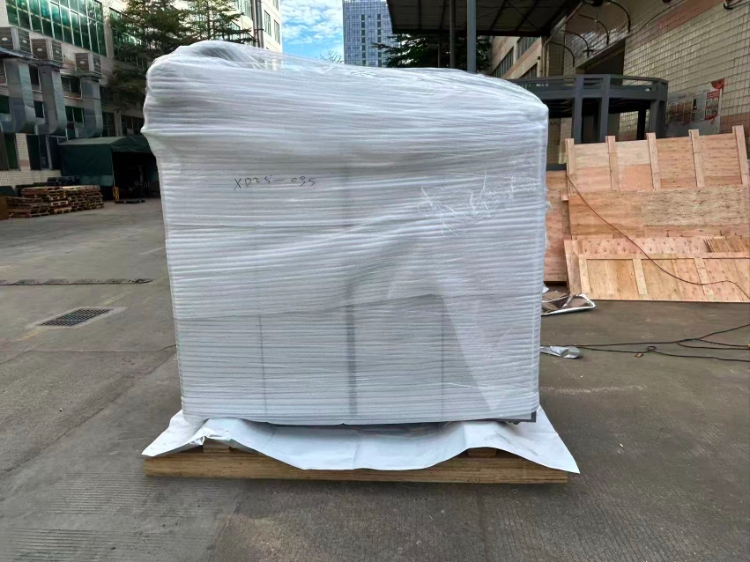

Today, the 10th set of single-color automatic LED UV curing equipment has completed packaging and inspection, and officially departed from the production base to Indonesia. It will be delivered to a long-term cooperative local printing and packaging customer for use in their bottle printing production line. This is a repeat order from the Indonesian customer based on the stable operation performance of the previously supplied equipment, marking a dual improvement in the product competitiveness and customer recognition of China's intelligent printing equipment in the Southeast Asian market, and injecting sustained impetus into industrial cooperation between China and Indonesia.

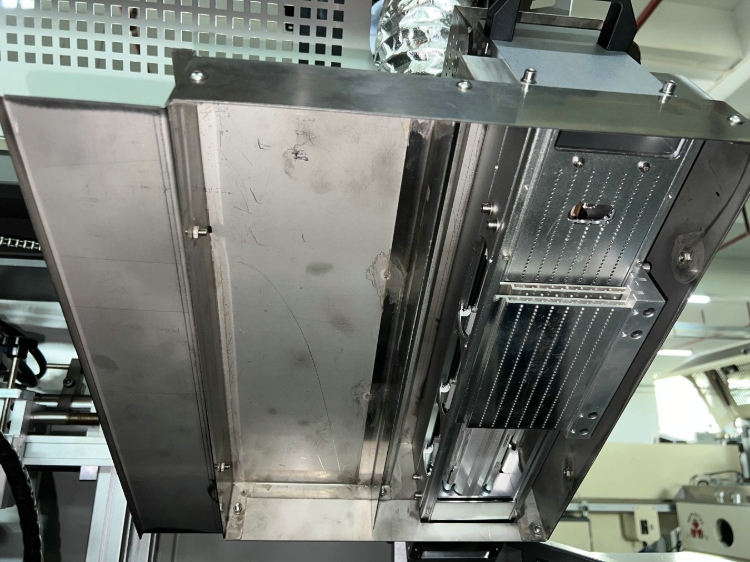

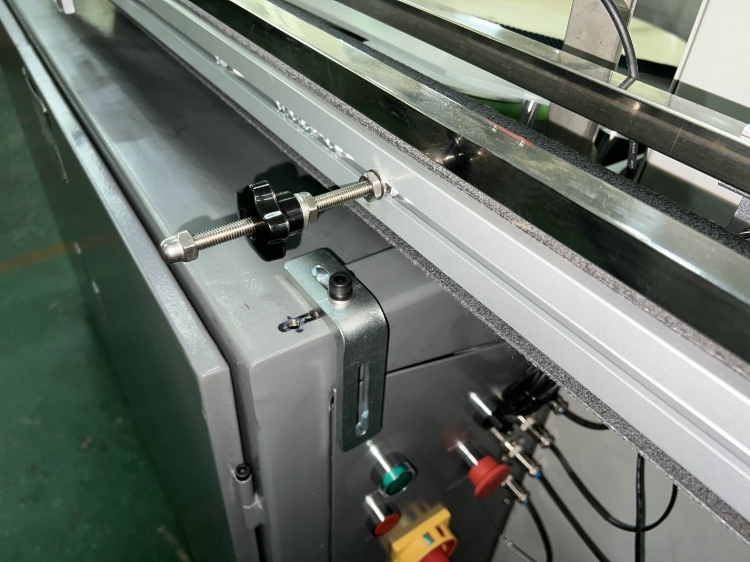

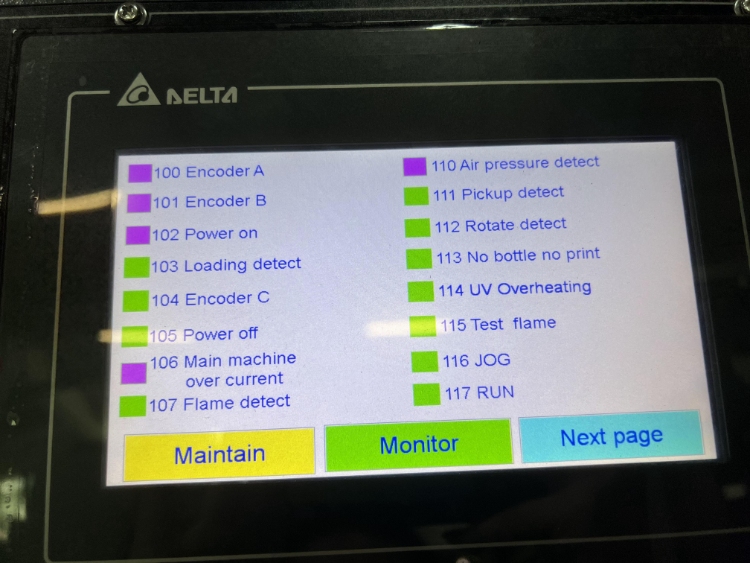

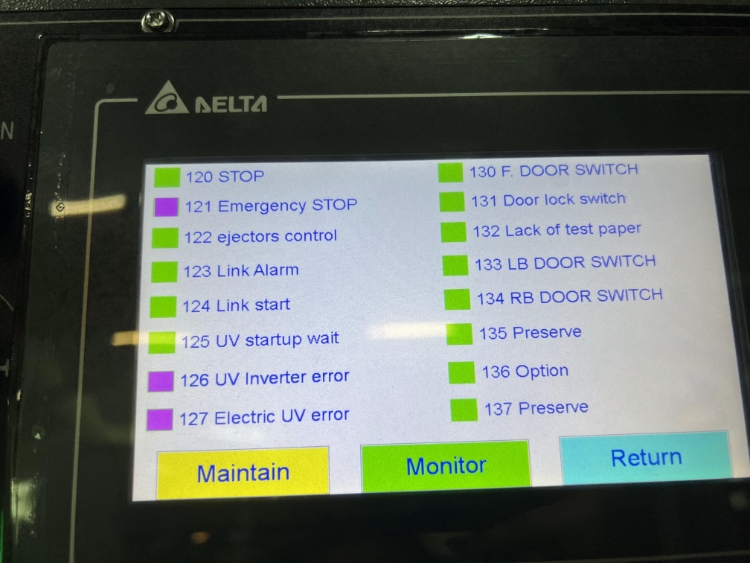

The equipment set shipped this time focuses on meeting the demand for efficient bottle printing production, and builds core competitiveness through "full-process automation + cutting-edge technology": the complete system integrates an automatic feeding machine, automatic flame treatment module, and single-color automatic LED UV curing main machine, forming an integrated printing process from material conveying, surface activation to UV curing. No manual intervention is required in the middle, which greatly improves production continuity and stability. Among them, the equipment is optimally designed for bottle printing scenarios, with a maximum production speed of 3,600 units per hour, perfectly adapting to the customer's large-scale production needs; the flame treatment module can accurately enhance the surface adhesion of bottles, solving the industry pain point of easy peeling of printed patterns; the LED UV curing main machine adopts the most advanced 365nm high-purity single-color UV curing technology, without infrared thermal radiation, and the temperature rise of workpieces is controlled within 3°C, effectively avoiding thermal deformation of bottle materials and adapting to precision printing on bottles made of various materials such as PET and PP. At the same time, the equipment is equipped with an independent constant current source control system and an intelligent heat dissipation module. The attenuation of light intensity stability is lower than that of traditional mercury lamp equipment, the service life is over 25,000 hours, and the energy consumption is only 1/60 of that of traditional high-pressure mercury lamp equipment, fully meeting the dual demands of energy conservation, environmental protection and efficient production in the Southeast Asian market.

It is understood that as a core growth driver in the Southeast Asian printing and packaging machinery market, Indonesia's regional market size is expected to exceed 8.5 billion US dollars in 2025. The compound annual growth rate of demand for bottle printing equipment in industries such as food and beverages, and daily chemicals reaches 12%-15%. Local enterprises generally face pain points such as low efficiency of traditional equipment, insufficient printing adhesion, and high energy consumption. However, the fully automatic integrated LED UV equipment delivered this time accurately meets the upgrading needs of the Indonesian market by virtue of its advantages of high production capacity (3,600 units per hour), complete process chain (flame treatment + UV curing), and low maintenance costs. The repeat order from this long-term customer is precisely based on the excellent performance of the previous equipment in terms of production efficiency, stability and comprehensive use cost, and also confirms the accurate grasp of regional market demand by domestic equipment manufacturers. Previously, through multiple technical communications and on-site tests, the two parties gradually optimized the adaptability of the equipment for bottle printing, and finally reached a long-term cooperation consensus.

In addition to the solid product strength, the comprehensive after-sales support system is the key to winning the continuous trust of long-term customers. To ensure that customers have no worries during the use of the equipment, the company has established an exclusive WeChat service group for each cooperative customer. The group is equipped with professional personnel such as technical engineers and after-sales specialists. Whether customers have needs for technical consultation, equipment fault diagnosis or after-sales maintenance, the company can respond immediately and provide solutions, ensuring the stable operation of the customer's production line with efficient and accurate services. This integrated cooperation model of "product + service" has become one of the important reasons for the repeat order from this long-term customer.