Product name:Self Tensioning Screen Frame

Model Number: STSF

Description:Self-Tensioning Screen Frame

Inner Size:30*40CM Price:136 USD

40*40CM Price:144 USD

50*60CM Price:160 USD

60*70CM Price:190 USD

The product feature includes

1. 2015 type slef-tensioing screen frame can replace hand Screen Stretcher after Slef-tensioing frame do not use any glue and other staffs.

2. The tension equality between the edge, each edge according to the allocated length 2-4 tension point, through to rally the uniform operation completely to enable the screen tension and requirements.

3. we can use the frame to make plate ,print just like using the traditional metal or wood frame

4. The repeated use of the finished silk screen mesh (main monochrome), the frame only need a set of stretch clamp, and it can finish stretching screen mesh. The screen frame is the same with traditional screen frame when we take down the one.

5.the screen frame edge can be order size, what kinds of different size frame strips can be composed of various sizes of the screen frame, can adapt to the size of the various patterns of different screen frame need;

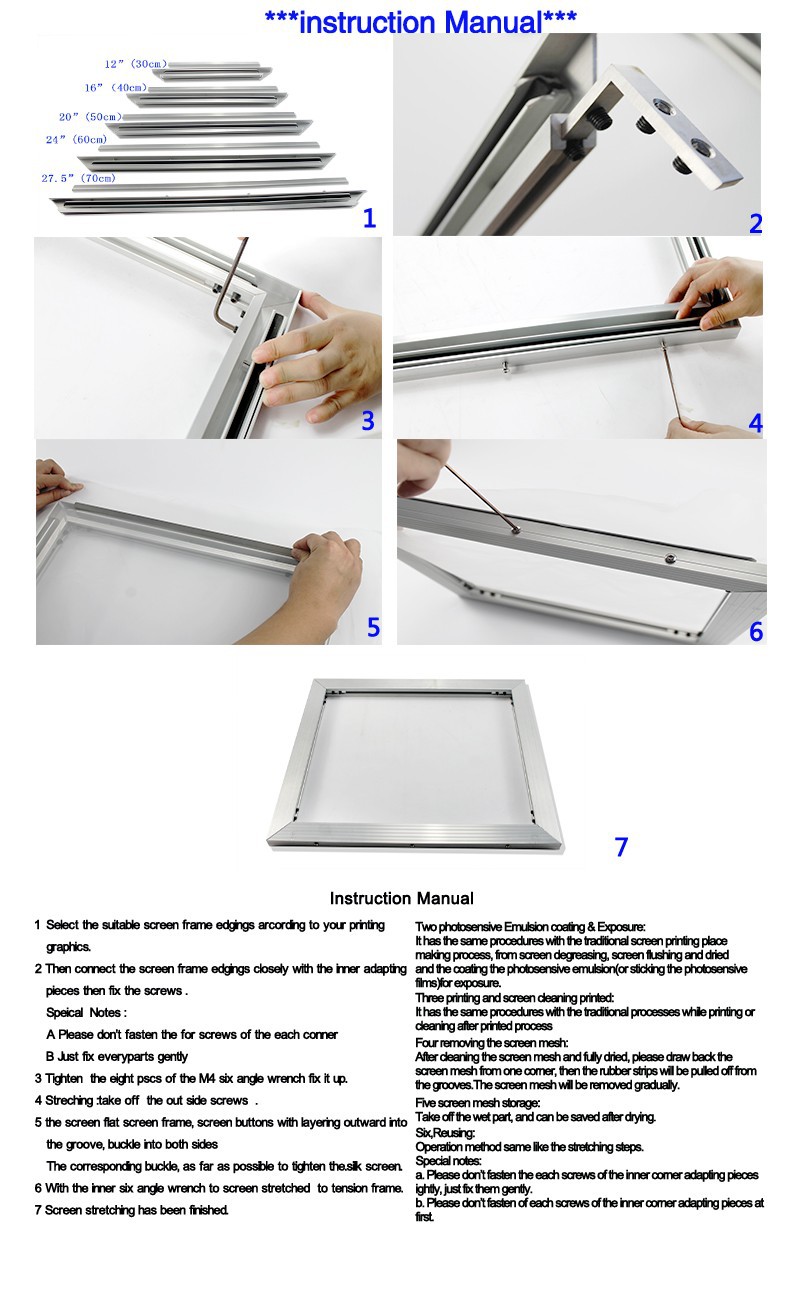

Self-tensioning screen frame installation and instruction manual

Before you install the self-tensioning screen frame you need check everything you have such as M3 and M4 Allen wrench 4psc corner adapting screen frame edging standard spare parts include aluminum screen frame edging screen frame edging sealing trench 2slider nut and 2 spare screws.

1. Select the suitable screen frame edgings according to your printing graphics. Then connect the screen frame. Connect the other frame edging with the adapting places &then fix gently.

2. Each four tennis frame uses seamless alignment, connector will be connected to the four corners, and using M4 Allen wrench will connect the top fastening screw. With the inner corner adapting pieces and then fixes the screws of the inner comer adapting places gently.

Special notes:

3. the net frame four tension screw loose, so that the net frame groove tightly inside the outer edge of U coast.

4. The right screen put on the self-tensioning screen frame edges, from the side to start the screen plate will screen flat pressure such as groove, then in the side of the screen flat straightened also pressed into the groove. Then the method is also pressing the screen on both sides of the screen.

5. M3 inner Allen key began on the edge of the outer hexagon screws evenly tightened, screen with inner frame groove naturally moves outward, the tension screen, that to achieve the required tension version of the screen .

6. the tension and the network is completed, the tension system net frame and traditional net frame exactly the same.

photosensive Emulsion coating & Exposure

It has the same procedures with the traditional screen printing place making process, from screen degreasing, screen flushing and dried and the coating the photosensitve emulsion(or sticking the photosensive films)for exposure.

printing and screen cleaning printed

It has the same procedures with the traditional processes while printing or cleaning after printed process

removing the screen mesh

After cleaning the screen mesh and fully dried, please draw back the screen mesh from one corner, then the rubber strips will be pulled off from the grooves. The screen mesh will be removed gradually.